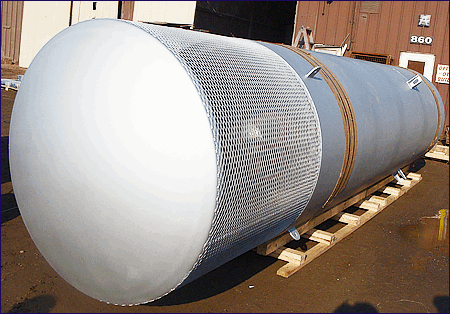

D13H-3 Discharge Silencers

Discharge Silencers - A rotary blower, such as a Roots URAI or RAM, delivers large quantities of air or gas at constant volumes for pressure or vacuum applications. These systems can produce excessive noise and vibrations. Stoddard discharge silencers provide a solution to control the noise associated with these blowers.

D33H-6 Intake Silencers

Intake Silencers - A rotary blower intake silencers is used for atmospheric air intake and pressure discharge applications. It is designed to reduce the pulsations and noise associated with rotary lobe, screw, and helical screw type blowers.

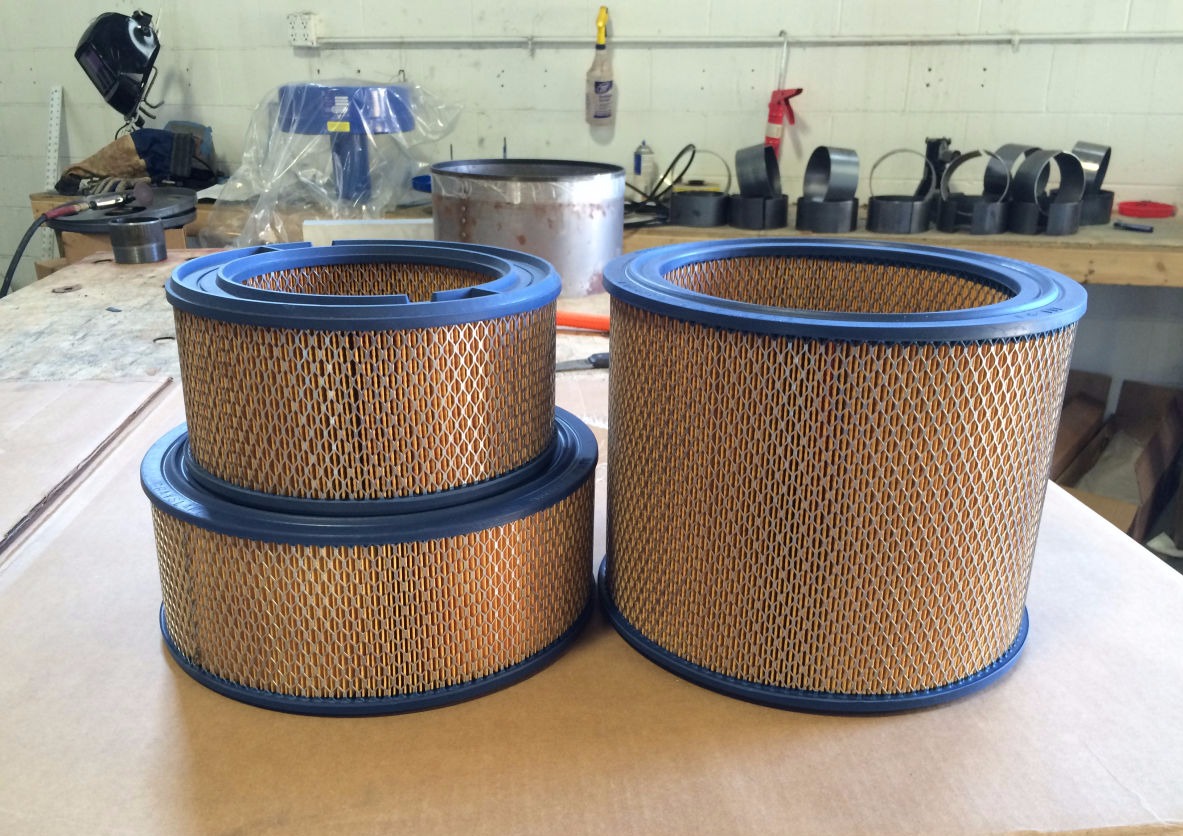

F21-246 intake filter silencer wF2-106 element

Air Filters and Intake Filter Silencers - Blowers, compressors and internal combustion engines all require clean air to work efficiently. Stoddard Silencers offers a full range of Intake Air Filters and Intake Filter Silencers for your air moving device or engine. A wide selection of available filter media allows you to select the filtration best suited for your application.